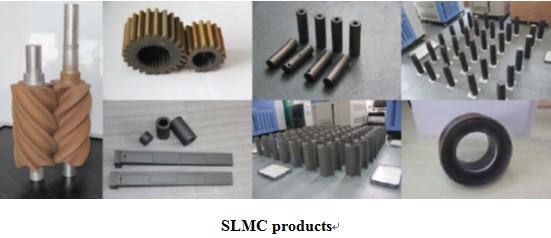

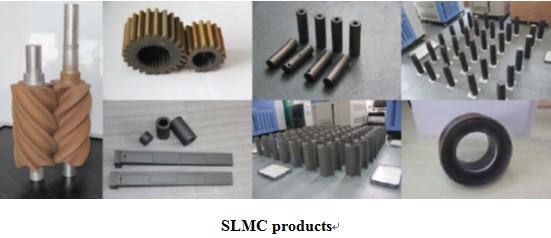

Achievements SLMC are mainly to solve the key technical problems (friction, wear, high-temp ablation, corrosion .etc) of mechanical parts served in varies transmission systems of equipment such as cylinder, piston, gear, axis, sliding rail, bearing and key pin. SLMC have been successfully applied to the products of more than 60 companies, and these products coated with SLMC possess excellent properties and market competitiveness. The social benefits of energy saving and consumption reduction were also gained. Function, technical parameters and advantages1、Solid lubrication or solid-oil synergy lubrication can significantly improve the wear resistance of equipments, which is obviously different from the single grease lubrication. 2、 SLMC show excellent properties preferred over GJB and MIL, including super low friction coefficient (≤0.09), high load bearing up to 100MPa, high-low temperature resistance (-60~260℃), salt spray corrosion (≤700h) and UV-radiation resistance (≤1400h). 3、 SLMC are regarded as environmental friendly materials due to their effects of energy saving and emission reduction. Applications SLMC has shown a great promise for friction and wear improvement in several fields, such as heavy equipment, auto-motorcycle, weapon, coal industry, textiles, oil-field chemical and instrumental industry.

|