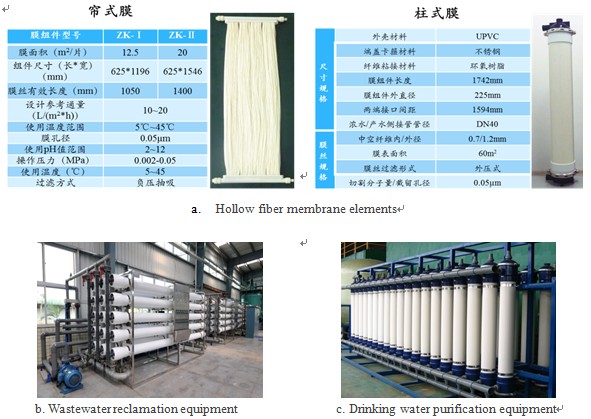

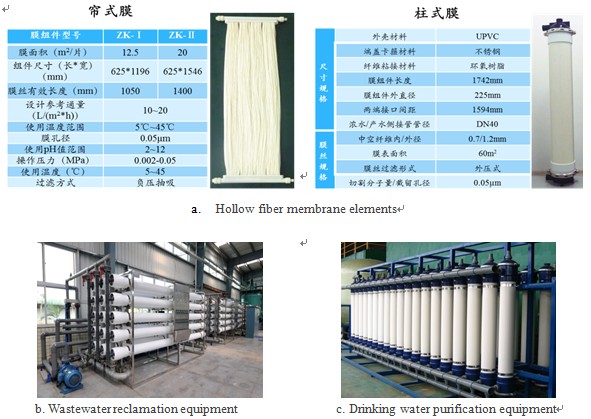

Achievements For the first time to adopt the micro/nano fiber reinforcement technology to prepare the high performance PVDF hollow fiber ultrafiltration membrane for water purification. The micro / nano fiber reinforced technology was used to increase the hollow fiber membrane strength and toughness. It was easy to solve the technical difficulties of the broken wire in the hollow fiber membrane industry. It has been implemented in the sewage treatment and drinking water purification in Shandong, Chongqing. A production line has been established with annual output of 50000 square meters of hollow fiber membrane, to produce sewage treatment membrane (curtain) and drinking water purification membrane (column). Function, technical parameters and advantages1. The micro/nano fiber reinforced hollow fiber membrane elongation at break of the similar products 3-4 times: in use less prone to the phenomenon of broken wires, extend service life, reduce customer operating costs and increase the stability of water purification; 2. Pressure response Membrane: In the backwash, the higher pressure can be expanded the aperture, facilitate pollutants discharge from the hole, reduce membrane fouling, and reduce backwash frequency. Applications Advanced treatment and reclamation of waste water; drinking water purification

|