| Location: Home > Research |

| Steam pyrolysis of sewage sludge |

|

|

Achievements

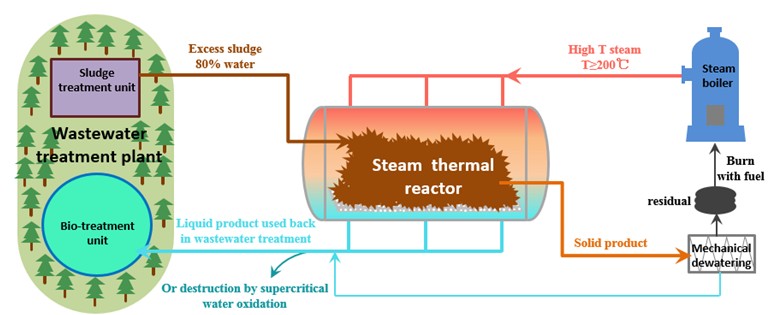

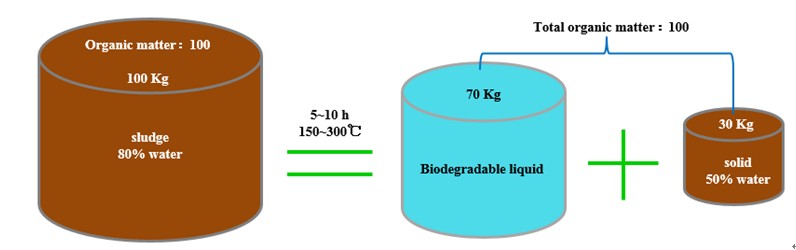

The use of independent innovation tank reactor with simultaneously solid liquid separation capability, and applying high temperature steam (120~200℃)to pyrolysis the sewage sludge, avoid the uneven heating, equipment scaling and corrosion etc. associated with the traditional thermal hydrolysis, volume reduction of 75% can be achieved for sewage sludge with 80% moisture and the leftover solid contains less than 50% moisture. Function, technical parameters and advantages1.New designed equipment is stable, safe, no stirring required, no fouling and corrosion for long term run. 2.Maximum operating pressure 2Mpa,maximum operating temperature 200℃,maximum load per batch 50 tons/batch, batch operating time less than 10 hour; 3. 75% volume reduction of sewage sludge, enhanced dewater ability, organic matters preserved in liquid and can be used a carbon source for microbial treatment, processing cost less than 100 RMB /ton. ApplicationsFor the treatment of concentrated sludge and dewatered sludge in waste water treatment plant.

|