| Location: Home > Department > Intelligence Manufacturing > Research and Development Center of Surface Functional Material and Engineering |

| Researchand Development Center of Surface Functional Material and Engineering |

|

|

Center brief: Research and Development Center of Surface Functional Material and Engineering focus on developing self-lubrication wear-resistant coatings, bionic super-hydrophobic self-cleaning anti-ice coating, drag and noise reducing coating and surface engineering technologies according to various work conditions in automobile, aerospace, weapon and power communication areas. The team has developed to 11 members, including 1 researcher(doctor supervisor) ,1 associate researcher (Master supervisor), 3 assistant researchers,2 intern researchers,1 engineer,3 masters. The research center have taken charge of 8 projects with the total funding of over 3 million yuan, including NSFC, national high-tech supporting project, Chongqing scientific supporting major project, “Western light” of Chinese Academy of Sciences and industrialization cooperative projects. By Sep. 2013, the research center had provided free service and technical support for more than 60 companies. Over 70 batches of the coated samples had passed approval test and 3 of them had been converted to products.

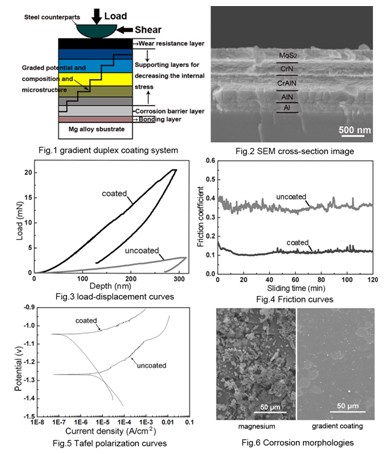

Research Directions: surface coating and technology of lightweight alloys This research investigates the damage behavior and failure mechanism of lightweight alloys based on the key scientific and technical problems of lightweight alloys (Mg, Al and Ti) serving at the synergetic situations (wear, corrosion .etc), but also focus on the design, preparation and properites studies of the nanostructure coatings (multilayer, composite, gradient, surface texture .etc). Self-lubrication Wear-resistant Integrated Coating Technology for Equipments: The direction aims at developing multifunctional coating with self-lubricating, anti-wear, impact-resistant, high-loaded, ablation-resistant, adhesion-resistant, antistatic and high-temp resistant properties to solve the key technical problems (friction, wear, erosion, corrosion, fatigue failure and lubrication seal failure .etc) of mechanical parts served in specific work conditions, and promoting its industrialization. Bionic self-cleaning super-hydrophobic coating technology: The research is mainly aimed at fabricating superhydrophobic surfaces with MNBS structure by conventional attempts to satisfy the urgent demand of anti-ice/snow and drag/noise reduction technology in aircrafts, electric power and underwater crafts fields. Furthermore, the research team focuses on the icing/anti-sticking interfacial behaviors and drag reducing mechanism, and promoting the engineering applications and industrialization of the self-cleaning coating.

Team Introduction The research team is consisted of 11 members, including 1 researcher(doctor supervisor) ,1 associate researcher (master supervisor), 3 assistant researchers,2 intern researchers,1 engineer,3 masters. The characters of the team is inter-disciplinarity, reasonable structure and cooperation-efficiency.

Markable achievements Group 1: surface coating and technology of lightweight alloys Based on the project supported by the Chinese Academy of Sciences Western Light (No. Y32Z

Group 2-- Self-lubrication and Wear-resistant muli-functional Coating Technology for Equipments:

The researchers have developed series of multi-functional coating materials with self-lubricating wear-resistant, impact-resistant, high load-bearing, adhesion-resistant properties to solve equipment industrial technical problems, The research achievement enhanced market competitiveness significantly.By Sep. 2013, the research center had provided free service and technical support for more than 60 companies in various fields such as heavy equipment, weapon, textile industry. Over 70 batches of the coated samples had passed approval test and 3 of them had been converted to products: friction-reduction coating for industrial printer frame (figure 7), self-lubrication and wear-resistant coating for piston (figure 8) and wear-resistant and protective coating for axises/piston column (figure 9).

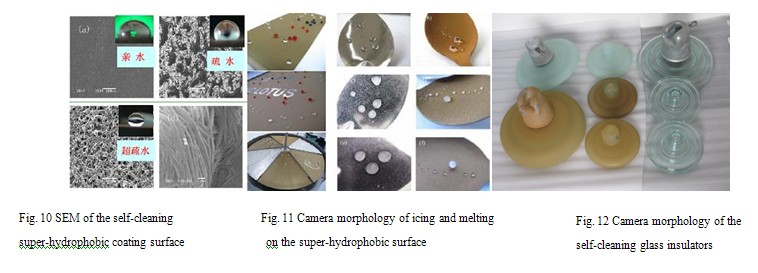

Bionic self-cleaning super-hydrophobic coating technology:

A novel bionic self-cleaning superhydrophobic polymer functional coating with MNBS structure by conventional attempts was successfully fabricated on the surface of some substrates (such as aluminum, copper, steel and glass) by one-step casting process. It revealed excellent drag and noise reduction, self-clean and anti-ice/snow performance in the applications of underwater crafts and transmission lines (Figure 10). The coatings possess excellent engineering application properties such as long-term stability, high cohesive strength, anti-temperature change and chemical-media resistance (Figure 11). The research has been published in related journal publications such as Advanced Materials. The research achievement has been applied for five national patents (three granted). At present, the research team is cooperating with national power company to develop “the self-cleaning glass insulators ”,and promoting the engineering applications and industrialization (Figure 12).

|