| Location: Home > Department > Intelligence Manufacturing > Intelligent Industrial Design |

| Intelligent Industrial Design Center |

|

|

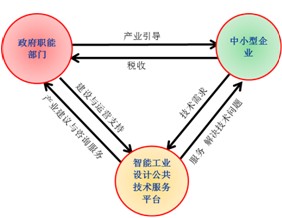

1. About IIDC

Intelligent Industrial Design (IID) is for simulation and optimum design. Design and simulation of mechatronic system, multi-physical system, dynamics, kinematics. Industrial products and production line to upgrade and to reform. Simulation and analysis of process in material area and numerical demonstration system in environment. Analysis, design and simulation of dynamics, kinematics and control system in robotic.IID Center do design service for small and medium manufactures firm. Corporation in research and development under the protection of trade secret and state secret, low invest.

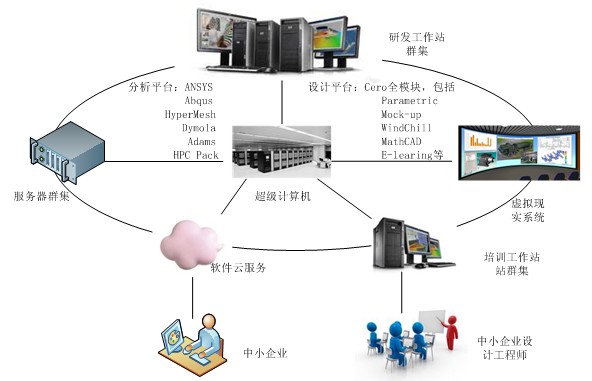

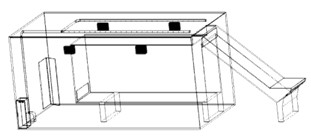

IID Center has been initially formed a high precision simulation software and high performance computer industry, super computer the CAE simulation based design service platform.Immersive virtual reality platform to supply virtual reality technology services for virtual production,virtual assembly, virtual factory etc. Build the mechatronic experiment platform to carry out various mechatronic experiments, mechatronic product development services.

Laboratory Equipment: 1) CAE technology platform l Graphics workstation group 2 Super computer 3 ANSYS 4 Pro/Engineer etc.

2) Virtual reality system l 3D Projector 2 Ultrasonic space Locator 3 Software of virtual reality system etc.

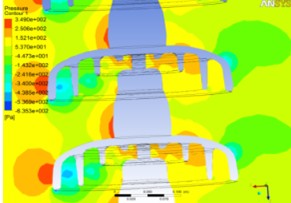

2. Research Areas Laboratory Equipment: The main research direction: 1.Simulation-based industrial design services for manufacturing 2. Structural analysis and optimization of mechanical products 3.Fluid dynamics、electromagnetic field (EMF)、Thermal design of electronic products and Multi-physics simulation Analysis 4. Analysis and control of Structure-borne noise 5.Co-simulation analysis of mechatronic hydraulic and control system 6.Simulation and design of critical process 7.Transform and upgrade services for tradition manufacturing 8.Design of virtual factory and virtual production line 9.Automation, transform and upgrade for old equipment , old production line 10.Industrial shape design 11.The development of new mechanical and electrical products for tertiary industry 3. Research Staff

4. Landmark Achievements 1. A company of tea fermentation tank automatic control system development.

The use of tea fermented tea fermentation tank principle, the green fermented black tea, the fermentation process requires the fermentation tank for automatic control of temperature and humidity to meet requirements of the fermentation. Completion of the fermentation tank for the production of tea production and its new value 20million RMB. 2.A company insulator Noise Analysis The company's insulator are exported to the United Kingdom, but because of the wind tunnel tests will produce a strong how ling, which does not comply with local environmental requirements. We use CAE analysis the reason of noise and propose optimization program, the new design samples In the wind tunnel tests significantly reduce the number of decibel showling, comply with local environmental standards.

3.Design of Gleason spiral bevel gear With the plane logarithmic spiral line during exercise in contact with the base cone of all the contact point as the starting point, establish the tooth surface by generating principle of coordinate transformation and spherical involute. To determine the influence of machining error of logarithmic spiral bevel gear contact performance by using local conjugate principle and the local synthesis method, and then the active tooth surface design and mechanism of the effect of technology on the design parameters. Simulation of cold extrusion process using plastic finite element method, and then optimize the design of cold extrusion die (including cooling system). High hardness quenching process in the core, carved on the basis of the polished surface of the way to improve die finishing die quality.

|