The 3D printing technology research team at the Chongqing Research Institute has designed a monitoring system based on a coaxial high-speed imaging system to monitor the entire forming process. This system can effectively identify key process phenomena and provide a new method for achieving full-process quality control. The relevant work has been published in internationally renowned journals such as IEEE Transactions on Industrial Informatics, Computers in Industry, and Materials & Design.

Specifically, the research paper titled "Prediction of powder bed thickness by spatter detection from coaxial optical images in selective laser melting of 316L stainless steel" uses machine vision technology to improve the coaxial imaging optical path and establishes a high-speed image acquisition system to monitor the process phenomena during the forming process, solving the long-standing problem of being unable to clearly observe the entire part formation process. This system effectively avoids the problems of limited field of view and poor imaging clarity in the current process monitoring systems, and achieves effective data collection of the entire metal 3D printing forming process.

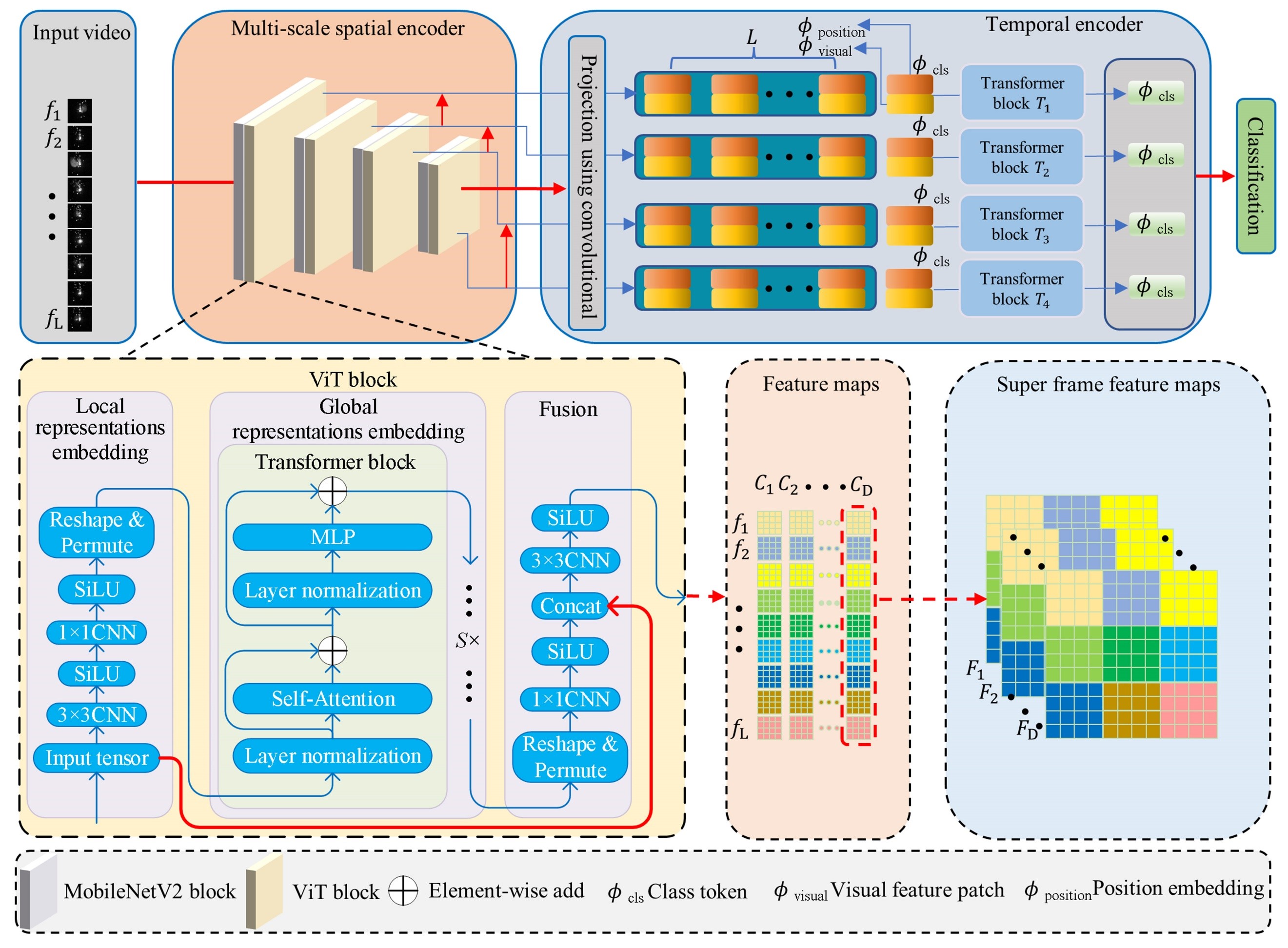

Additionally, the research paper titled "2-D Transformer-Based Approach for Process Monitoring of Metal 3-D Printing via Coaxial High-Speed Imaging" proposes an improved video understanding model to solve the problem of being unable to accurately identify defect features from the metal 3D printing process phenomena. These results help improve the stability and reliability of the forming process and provide a theoretical basis and technical means for achieving intelligent process monitoring of metal 3D printing.

The above work has been supported by the National Natural Science Foundation of China, the National Key Research and Development Program of China, and the Youth Innovation Promotion Association of the Chinese Academy of Sciences.

Link to relevant papers:

https://doi.org/10.1109/TII.2023.3314071

https://doi.org/10.1016/j.compind.2023.103975

https://doi.org/10.1016/j.matdes.2021.110301

https://doi.org/10.1016/j.jallcom.2021.163406

Figure 1. Schematic diagram of the improved coaxial machine vision system optical path layout and equipment photo

Figure 2. Architecture diagram of the proposed multi-scale video understanding model